School of Design and Manufacturing

NEC 211

919 Campus Drive

Big Rapids, MI 49307

(231) 591-2511

(231) 591-2640

MFTE-110, Introduction to Machining Processes

In this course focus is placed on machining fundamentals that are used in producing manufactured components. This course covers precision measurements, precision instruments, metrology applications, tooling applications, machining calculations, machining processes (i.e.: drilling, milling, turning, and grinding) process planning, and speeds and feeds. Classroom discussions and related activities support the projects in the corresponding lab courses.

MFTE-113, Build Machined Components

In this course focus is placed on direct machining lab experience to produce machined components. This course covers general shop safety, equipment startup and operation, machine setups, work holding setups, cutting tool setups, workpiece locating, and application of the core machining processes (i.e.: sawing, drilling, milling, turning, and grinding). Lab projects provide students the opportunity to apply the corresponding lecture material directly with lab activities.

MFTE-130, Tooling Systems Operations

In this course focus is placed on developing an in-depth understanding of tooling systems and standards used in producing manufactured components and manufactured assemblies. This course covers tool design specifications, manufacturing specifications, tooling assemblies, and tooling component applications Emphases is placed on (i.e.: processing, design, construction, and assembly), cutting tool selection, material usage, heat treat applications, threading systems, indexing systems, program documentation and cost estimating. Lecture activities including a major program quoting project. Classroom discussions and related activities support the projects in the corresponding lab course.

MFTE-131, Design and Build Manufactured Tooling Systems

In this course focus is placed on developing skills directed toward producing manufactured assemblies. This course covers the application of advanced machining operations, in-depth application of manufactured tooling concepts (i.e.: design, construction, assembly, and tryout / troubleshooting), and application of specialized tooling systems. Lab activities including a major build project providing students the opportunity to utilize and apply the technical material covered in the corresponding lecture course.

MFTE-140, Basic CNC Programming

In this course focus is placed on developing an in-depth understanding of the process used in programming CNC machining equipment. This course covers an overview of CNC technology, coordinate data input, NC program formatting and layout, G-code programming, and an introduction to CAM programming. Classroom discussions and related activities reference both milling and turning equipment and support the projects in the corresponding lab courses.

MFTE-141, CNC Machine Operation

In this course focus is placed on developing skill in programming and operating CNC machining equipment. This course covers the construction, maintenance, startup, and operation of CNC milling and turning equipment. Numerous lab projects provide students the opportunity to apply the science and methodology covered in the corresponding lecture course.

MFTE- 220, Advanced CNC Programming

In this course focus is placed on developing an in-depth understanding of the programming of CNC machining equipment using advanced programming technologies. This course covers developing toolpaths from both surface geometry and solids, automating toolpath development routines, programming wire EDM burns, and 4th and 5th axis machining. Classroom discussions and related activities support the projects in the corresponding lab courses.

MFTE- 222, CNC System Utilization

In this course focus is placed on developing skill in applying advanced programming technologies and utilizing CNC machining systems. This course covers, maintenance, startup, and operation of wire EDM equipment, as well as high-speed machining applications, and 4th and 5th axis machining applications. Numerous lab projects provide students the opportunity to apply the science and methodology covered in the corresponding lecture course.

MFTE-230, Advanced Machining Operations

In this course focus is placed on programming and conducting advanced machining operations. This course provides student the opportunity to interact and utilize advance machining operations by identifying, programming, and applying advanced machining methods. Computer Controlled Laser operations, Electrical Discharge Machining operations, Five-Axis Milling operations, Live Tooling Lathe operations, and Sinker Style Electric Discharge Machining operations are included in this advanced course of study. Lab projects include multiple projects that provide students the opportunity to develop, program, operate and apply advanced metal removal operations.

MFTE- 240, Design & Build Project

In this course focus is placed on a customized design and build. This course provides student the opportunity to select a specific project, design the project, manufacture the components, and build the system. The design and build phase of the project is assessed, documented, and monitored for the extent of the course. An in-depth understanding of program management, program development and manufacturing operations (i.e.: design, construction, component assembly, tryout, and troubleshooting) is the basis of this course. Lab projects include one major project build that provides students the opportunity to apply conceptual ideas into workable assemblies. This course is designed to enhance and facilitate senior projects in related fields of study (i.e.: Mechanical, Product Design, Welding and Automotive Technology).

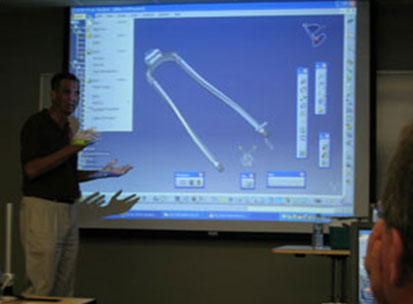

PDET-122, Parametric Modeling

This is an introductory course in which the student will focus on techniques for developing 3-dimensional computer-generated models. Students will develop skills using parametric based Computer Aided Design software. The student will receive exposure to basic 3-D modeling principles used to generate robust models in 3-D space.

MATL 240, Intro to Material Science

Introduction to the study of the science of engineering materials: metals, polymers, and ceramics. Included in topics of study are atomic structure and bonding, properties selection, and testing of materials, failure modes, methods of production and fabrication, methods of changing properties including heat treatment of metals, alloying and surface treatments, mechanical working, composites and compound bonding. The common classification systems used to identify the various engineering materials are also covered.