Product Design Engineering Technology Program Coordinator

by John Smith - Oct. 19, 2020

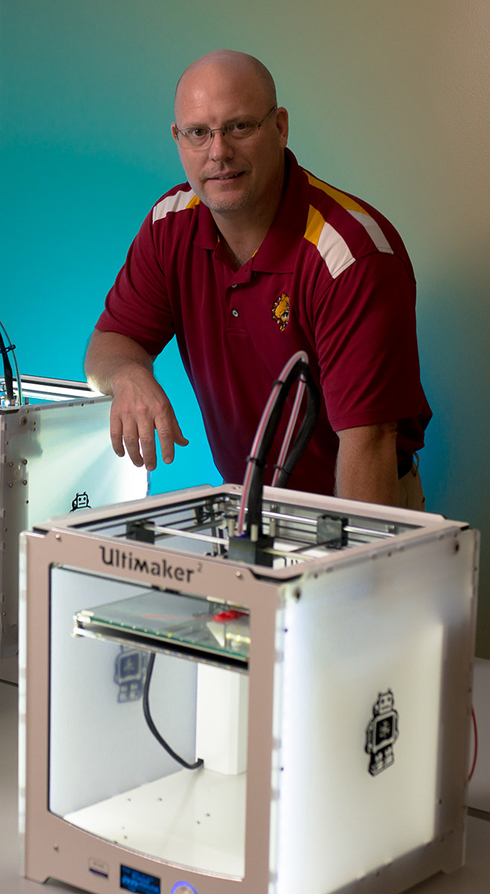

Product Design Engineering Technology Program Coordinator Bill Koepf came to Ferris

State University as a student more than 30 years ago. He came with practical experiences

from his childhood on a farm near Sebewaing, with a desire to be active in the design

and manufacturing industry.

“Growing up on a farm was a great experience. It allowed me to develop a desire to

find out how things work and prepared me for what was required in the PDET program,”

Koepf said. “That background proved to be an asset in my pre-professional development

as well.”

Koepf earned his Associate of Applied Sciences degree in Technical Drafting And Tool

Design in 1989 and completed studies for his Bachelor of Science in Product Design

Engineering Technology in 1991. Though he has near 20 years of experience as a member

of the College of Engineering Technology faculty and is entering his fifth year as

Ferris’ Product Design Engineering Technology program coordinator, Koepf said his

first professional roles after graduation helped to form the instructional philosophy

he follows today.

“I gained great experience in plastic injection molding, project engineering and leadership

in the manufacturing process at Blue Water Plastics in St. Clair, near Detroit and

in my time at Port Huron Molded Products,’ Koepf said. “I did a little bit of everything,

with a desire to accept any opportunity, so I could learn new things. When my employer

needed robotic equipment programmed, I taught myself what was necessary to set that

up. I would ask engineers questions and go about learning what it took to accomplish

the goal. The PDET program and the instructors prepared me well, getting us as students

to be confident in our abilities and to rely on what we had learned in our PDET classes

and labs.”

As Koepf and his wife Tina began to raise their family, they decided to return to

West Central Michigan, where she had grown up. Bill was considering industrial opportunities

in the region, but his attention was drawn to a job posting at his alma mater.

“Ferris was a great place to learn and live, but I did not head into my career with

any intention of returning to the university,” Koepf said. “The job description, with

its duties and responsibilities, were very attractive, and I wanted to try something

new. I did not present myself to be an academic, explaining that my approach to instruction

would be in line with my practices as a design engineer. I have always sought to help

students understand what they need to learn and master to be successful and why it

is important for their professional development. I believe they have always found

me to be a straight shooter who does not pull punches, with a clearly established

bar for what they need to accomplish in the program.”

Koepf said he gained valuable experience in his years teaching alongside Goosen, as

they worked to promote their program as an excellent resource for product design talent

who are well versed in computer-aided design.

“We were able to develop a pervasive CAD environment, and to this day the goal is

to incorporate that learning in more aspects of the program,” Koepf said. “Our students

are ready to make use of their product design experience and leave us capable of being

successful in the product design cycle.”

Koepf said the Product Design Engineering Technology program has been a long-term

success by remaining lean in its faculty roster and staying focused on providing contemporary

and necessary technology to promote students’ learning and experiences. By adopting

the active-based learning pedagogy, they could bring the practical nature of product

development into the classroom.

“There was a three-dimensional printer available to students here when I was completing

my degree,” Koepf said. “It was not widely accessible at that time, but we have worked

to build our resources and now have eight 3-D printers. We are glad to offer our students

a much wider opportunity. There are also more worktables, monitors and a video switching

system in our labs, to help our students be creative and gain valuable design experience.

Our students came to Ferris because they want to learn how to do something. It has

always been the department’s goal to help them build their abilities and gain those

experiences they desire.”

Koepf became PDET Program Coordinator as the 2015-16 academic year began, as Goosen

assumed greater administrative responsibilities in the College of Engineering Technology.

Bill credits his tenure-track peer, assistant professor Luke Hedman with buying into

the traditional goals of the program and bringing new energy, to build on the opportunities

and offerings available to students.

“He developed an experimental course, PDET 220, called Maker Culture,” Koepf said.

“It is a general education course that allows students to become immersed in many

aspects of just making stuff. It shows students from any program that they can be

a part of product development.”

As the number of 3-D printers and other equipment grew, Koepf went about making it

known to other CET programs and colleges across campus that this technology was available

and accessible. What started out several years ago in Room 110 of the Swan Building

has grown into an area known as the Makerspace, which now encompasses two rooms in

the National Elastomer Center, or Plastics Building. Koepf said they are excited about

the potential this facility offers to their college and the university in general.

“We expect that the Makerspace will be a great benefit to the learning experience

for many of our College of Engineering Technology programs,” Koepf said. “The ultimate

goal of this facility is to provide students the fundamentals and resources necessary

to be able to make the most of their opportunity.”

Some of the equipment available to students using the Makerspace includes a computer

numerical control or CNC router and a desktop wire bender. Koepf said the collaborative

efforts of faculty and staff bring them closer to producing the filament necessary

for their 3-D printers on campus, which he believes to be a unique development for

a collegiate facility.

“I am happy to be an overseer, who can link our students to the talent that is available

in other areas of the campus,” Koepf said. “We staff the Makerspace with student lab

workers, so anyone with the need and interest can swipe their ID and have free access

to the facility. That means they have full access to our equipment and technology,

along with the opportunity to use whatever materials we have available to complete

their project and gain from the experience. The lab workers are ready to help them

print their file and can train them to set up their project. Whether it is a PDET

student or someone in another university program, it is important to be supportive

and ready to offer access, so we can meet their needs.”

Koepf said the Michigan College of Optometry is an example of a university partner

who found the Makerspace as a resource to further their pursuit of instructional excellence.

“It is a beneficial relationship for their learning and our students,” Koepf said.

“We have been able to develop certain products for them through computer-aided design

or CAD work. Product Design Engineering Technology students who require a capstone

project to complete their studies are often assigned to assist in such collaborations.

That provides them a leadership role in a true activity-based learning exercise.”

The spirit of collaboration is not restricted to Product Design Engineering Technology

students and colleges on the Ferris campus. Koepf said industry professionals receive

on-site training in concepts like geometric dimensioning and tolerancing.

“We have provided this support to Avon Protection Systems in Cadillac, Amerikam in

Grand Rapids, and Precision Aerospace, another manufacturer in the Grand Rapids area,”

Koepf said. “These relationships can create benefit for our students, as we strengthen

our connections in the manufacturing centers of this region.”

The outreach and collaborative efforts Koepf and Hedman take up also involve the development

of articulation agreements with Mid-Michigan Community College, in Harrison; Mott

Community College, in Flint; Kellogg Community College, in Battle Creek; and Kalamazoo

Valley Community College.

“We want to be seen as a primary destination for CAD students, who are looking to

go beyond their associate degrees,” Koepf said. “If we can be adaptive and fluid,

that should play well with those prospects. Product design work is never the same

routine, so we want to be as flexible as possible in our process, to encourage students

to consider us as the place to achieve their goals. I am glad to have all the experience

that Rich Goosen designed in our program at Ferris, with hopes that Luke and I can

uphold and advance that mission.”

Koepf and Hedman focus on making inroads with new students while they maintain a brisk

and active instructional schedule.

“I am a tenured member of the faculty; Luke is on the tenure track,” Koepf said. “We

have between 70 and 80 students in the Product Design Engineering Technology program

most years. We offer classes at the Applied Technology Center on Grand Rapids Community

College’s campus in the evening. It requires a great deal for us to teach the subject

matter, develop our content and stay focused on our students’ academic success.”

Part of that content development in the Product Design program is the establishment

of a “0 to 4” alignment, developed by Rich Goosen, which allows students to use as

many as 19 to 21 credits in their bachelor of science program to broaden their capabilities.

“That cluster of credits is open, with respect to this particular curriculum,” Koepf

said. “Our students then have flexibility to achieve a Business minor, or take a number

of Plastics Engineering courses. There is even room to take up a foreign language,

so the student might be capable of working overseas. It allows us to work with students

from all backgrounds and with all interests who may be capable of success in our program,

because they deserve the opportunity to customize their skill set.”

Koepf believes that through his own experience as an alumnus and instructor, based

on the foundational work done under Rich Goosen’s leadership, modified and advanced

through collaboration with Luke Hedman, places the Product Design Engineering Technology

program in a prime situation to meet industry needs with qualified candidates.

“Regional industry is beginning to understand that our students come to them with

design engineering experiences, and a strong background in CAD,” Koepf said. “Because

our students pursue excellence and develop these abilities, we are proud to successfully

place each of our graduates, with more opportunities available to us than we can fill.

I knew my abilities translated well to what industry partners were seeking when I

completed my degree. When I returned and joined the department as an instructor, I

found out how much is involved in doing this job well. I am thankful there is such

collegiality in our department and all of the College of Engineering Technology. I

feel I am still learning my craft, now 20 years into the job, and am grateful that

I am full of ideas on how we can expand and improve our processes. I believe our program

stacks up with anyone’s, and am proud of the graduates that we provide to our industry

partners.”

John Smith is the communications specialist in the News Services and Social Media

department of University Advancement and Marketing.

For others featured in the Faces of Ferris series, visit:

https://ferris.edu/HTMLS/news/faces/